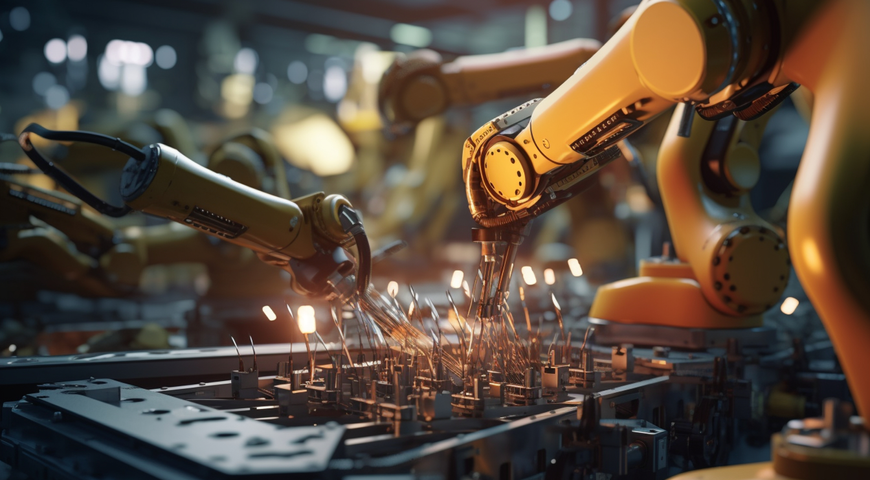

When we’re talking about data protection and security in the manufacturing industry, we are referring to the practices and controls manufacturers implement to protect sensitive information while also ensuring the integrity, confidentiality and availability of data in their networks, systems and processes.

Data protection and security also involves protecting critical data from unauthorized access, modification, disclosure and loss. It also plays an important role in preventing cyberattacks and disruptions that could impact manufacturing operations and business continuity.

Risks associated with data loss in the manufacturing industry

Data loss in the manufacturing industry can have many adverse consequences, ranging from operational disruptions and downtime to supply chain issues to the loss of business continuity. These can be serious consequences, leading to unhappy customers, lost revenues and compliance and legal outcomes.

Maintaining continuous uptime for factory floor operations is a critical for manufacturing business profitability: minutes of downtime can equal millions of dollars in lost sales, delayed revenues, wasted capacity and higher fulfillment costs. The challenge of maintaining near-100% uptime is exacerbated by the frequent lack of on-site tech support resources to address downtime sources like the failure of servers that control automated processes.

Other areas of the manufacturing business may have less sensitivity to momentary interruptions of operations, but still cannot afford extended downtime periods or the loss of critical data due to cyberattacks, tech infrastructure failures, human error or natural disasters.

In particular, ransomware has grown in recent years to the point where it has become the leading cyberthreat to manufacturing, wreaking costly data theft and downtime on businesses of every size. Ransomware attacks have become increasingly sophisticated and frequent, with cybercriminals wielding devious new tactics to get victims to pay for the restoral of their data and uptime.

Additionally, the entire manufacturing industry faces other challenges that may lead to data loss in the manufacturing industry. For example, skilled, experienced cybersecurity professionals are hard to recruit, hire and retain, leaving many manufacturing companies with real gaps in their cybersecurity workforce. Additionally, these resources are becoming increasingly expensive, which may put them out of reach of some companies.

Best practices for data protection and security in the manufacturing industry

To mitigate these risks, manufacturing companies should implement robust data protection measures, including regular data backups, secure storage, access controls, encryption, employee training, cybersecurity measures and disaster recovery plans.

Manufacturers should also consider implementing the following best practices:

Strengthen network security

Manufacturers are increasingly interconnected through digital networks and internet-connected devices Robust cybersecurity measures are necessary to defend against cyberthreats, such as hacking, malware, ransomware and phishing attacks. This includes implementing firewalls, intrusion detection systems, antivirus software and conducting regular security audit to protect their networks.

Manufacturers can further enhance network security with strong access controls, regular patch management and employee training and should always use encrypted communication protocols, VPNs and network activity monitoring.

Focus on employee education and training

Employees play a critical role in maintaining data security. Training programs and awareness campaigns help educate employees about data protection best practices, such as password security, phishing prevention and proper handling of sensitive information.

Secure manufacturing equipment and infrastructure

Manufacturers can enhance the security of their equipment and infrastructure by conducting risk assessments, implementing physical access controls, network segmentation and regular software updates. By adopting these measures, manufacturers can protect their equipment and infrastructure from threats, ensuring operational continuity and minimizing potential disruptions.

Ensure compliance with regulations in the manufacturing industry

Manufacturers may be subject to various data protection regulations, depending on their industry and geographical location. Compliance with regulations such as the General Data Protection Regulation (GDPR) or industry-specific standards like the International Organization for Standardization (ISO) 27001 helps ensure data protection and security.

Common questions people also ask

How does data security protect the manufacturing industry? Data protection and security provide significant benefits to manufacturers. They help safeguard intellectual property, trade secrets and sensitive manufacturing data, preserving a company's competitive advantage. By preventing unauthorized access and data breaches, manufacturers can protect their innovations and prevent competitors from gaining an unfair advantage.

Additionally, robust data security practices ensure uninterrupted manufacturing operations by maintaining the integrity and availability of critical data. This enables manufacturers to optimize processes, make informed decisions and improve efficiency, resulting in enhanced productivity and cost-effectiveness. Furthermore, adhering to data protection regulations and standards ensures compliance, avoids legal penalties and maintains trust with customers and regulatory authorities. By prioritizing data protection and security, manufacturers can bolster their competitiveness, maintain customer confidence and mitigate risks associated with data breaches and unauthorized access.

What are the consequences of data loss in the manufacturing industry?

Data loss in the manufacturing industry can have several significant consequences. Here are some of the potential impacts:

· Production disruptions: Data loss can lead to disruptions in production processes. For example, consider the fact that manufacturing relies on highly accurate, up-to-date data for various aspects such as inventory management, supply chain coordination, scheduling and quality control. Without access to critical data, production schedules may be disrupted, leading to delays, inefficiencies and potential loss of revenue.

· Downtime and Increased costs: Data loss can result in significant downtime as manufacturing systems may need to be shut down or put on hold until the data is recovered or restored. This downtime can result in lost productivity and increased costs. Additionally, manufacturing operations may need to be rescheduled, leading to overtime expenses or the need for additional resources to meet deadlines.

· Quality control issues: Data loss can impact quality control processes in manufacturing. The loss of data related to product specifications, quality standards or testing procedures can lead to compromised product quality. This can result in increased defect rates, customer complaints and potential recalls, all of which can damage the reputation of the company and incur financial losses.

· Supply chain disruptions: Manufacturing companies rely on data to manage their supply chains effectively. Loss of data can disrupt the flow of information between suppliers, manufacturers and customers. Lack of visibility into inventory levels, demand forecasting or shipment tracking can lead to supply chain inefficiencies, delays and increased costs.

· Compliance and regulatory issues: Many manufacturing industries are subject to regulatory requirements and compliance standards. Data loss can result in the failure to meet these requirements, leading to potential legal and financial consequences. For example, if critical data related to product safety, environmental compliance or employee safety is lost, it can result in violations and penalties. See more on this topic below.

· Loss of intellectual property: Manufacturing companies often deal with sensitive and proprietary data, such as product designs, manufacturing processes, trade secrets and customer information. Data loss can expose this valuable intellectual property to unauthorized access, theft or misuse. Such incidents can lead to compromised competitive advantage, loss of market share and legal disputes.

· Reputational damage: Data loss incidents can harm a manufacturing company's reputation. Customers, partners and stakeholders may lose trust in the organization's ability to protect their data or maintain reliable operations. Negative publicity and word-of-mouth can further impact customer loyalty and future business opportunities.

What are some best practices for complying with regulations specific to the manufacturing industry?

Establishing compliance programs tailored to the manufacturing industry is essential. To comply with regulations specific to the manufacturing industry, organizations can follow key best practices, including developing policies, procedures and guidelines addressing regulatory obligations, and employee responsibilities and training programs. Proper documentation and record-keeping of compliance activities are necessary for audit purposes.

As described earlier, employee training and awareness play a vital role. Educate employees on compliance requirements, including workplace safety, data protection and ethical conduct. Supplier and contractor management should be implemented, ensuring compliance throughout the supply chain.

Regular auditing and monitoring processes help evaluate and address compliance effectiveness. Engaging legal and regulatory experts can provide valuable guidance. Embrace a culture of continuous improvement by regularly reviewing and updating compliance programs.

Better ways to keep manufacturers safe

To mitigate the consequences of data loss, manufacturing companies should implement comprehensive data protection and security measures, including data backup and recovery strategies, robust cybersecurity measures, regular data audits and effective disaster recovery plans.

Acronis has a proven advantage in this scenario: the ability to restore failed factory-floor process control servers in a matter of minutes from images of their OS, applications and data stored in local physical servers or virtual machines.

Additionally, the Acronis Cyber Protect solution is simple and yields critical, very fast restoral of factory-floor operations after an OT server fails. When an OT server fails, Acronis re-images a new one — either to the same hardware or to a different model of server or to a virtual machine — that can be automatically substituted for the failed one with no skilled local IT support required.

Acronis Cyber Protect also provides integrated cybersecurity and data protection (the classic Acronis Cyber Protect value proposition: backup, DR, endpoint anti-malware, URL filtering, patch management) to other functional areas of the manufacturing business, including back office systems (office productivity, finance, HR, etc.), MRP systems, supply-chain management systems, and other applications unrelated to real-time factory floor operations.

And, with the Acronis Disaster Recovery add on, Acronis Cyber Protect helps you to stop losing money when critical workloads, files, or applications become unavailable. Ensure instant availability with quick failover to the cloud, making your infrastructure resilient and cost-efficient – and ensuring business continuity.

By implementing comprehensive data protection and security measures, and products like Acronis Cyber Protect, manufacturing companies can mitigate the risks associated with data breaches, intellectual property theft, operational disruptions and reputational damage – such as regulatory noncompliance litigation, which can result in ruinous fines that could potentially put your business OUT of business.

Learn more by visiting https://www.acronis.com/en-eu/solutions/business/ today.

About Acronis

A Swiss company founded in Singapore in 2003, Acronis has 15 offices worldwide and employees in 50+ countries. Acronis Cyber Protect Cloud is available in 26 languages in 150 countries and is used by over 20,000 service providers to protect over 750,000 businesses.